Are You Using the Right Deicers for Your Parking Facility?

Are You Using the Right Deicers for Your Parking Facility?

Building a new parking facility or repairing an old one is an expensive process, which is normally done with an eye toward long-term life-cycle costs. This is accomplished by using a good design, building with top-of-the-line materials, utilizing a strong maintenance strategy and using non-chloride acetate deicers.

Building a new parking facility or repairing an old one is an expensive process, which is normally done with an eye toward long-term life-cycle costs. This is accomplished by using a good design, building with top-of-the-line materials, utilizing a strong maintenance strategy and using non-chloride acetate deicers.

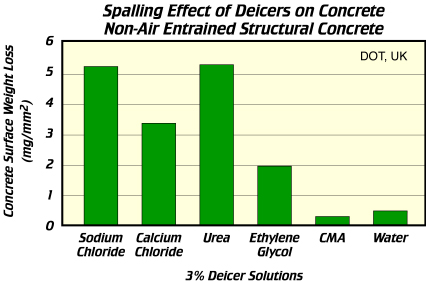

All this planning can be undone if chloride-based or urea-based deicers are used for snow and ice control. The result is expensive premature damage from corrosion, spalling, damage to sealing compounds, and damage to the environment through runoff into storm water.

Often times, the short-term decision to use deicers is based on the upfront cost of the deicer and performance instead of considering the long-term damage to the facility. This can be a very costly approach in the long run, resulting in millions of dollars in repair or replacement. With repair, there is the cost of lost revenue and inconvenience to the customer to consider too. Even sand use is costly when you consider cleanup costs of sweeping, drain cleanouts, grinding off of markings and membrane damage.

Many parking consultants and engineers today are recommending in their maintenance manuals that non-chloride acetate deicers be used in order to maintain the warranty and to extend the life of the facility. These deicers include pelleted acetate deicers like calcium magnesium acetate (CMA), 97 percent anhydrous sodium acetate deicers (NAAC) which work to 0 degrees F and liquid potassium acetate deicers (CF7). Their information comes from studies of corrosion testing by the FederalHighway Administration, state departments of transportation, universities, and several other sources of independent testing. They have also relied on information from long-time users in the field that have proven these acetate deicers to be safe for steel in reinforced concrete garages, concrete, sealing materials and the environment.

The acetate-based deicers like CMA, NAAC and CF7 can provide a facility manager a safer deicer choice for the snow and ice management strategy. The strategy can be developed from past experience, temperature ranges for the region, type of winter storms and whether an anti-icing or deicing approach should be made.

Periodic training of the maintenance staff is important to get the most out of the acetate deicers used and to reduce the potential for under or over application. Short training videos and detailed application guidelines are available to the proactive manager. You may wish to contact your garage consultant for his recommendations or review the non-chloride, acetate-based deicers’ fact sheets available online.

Periodic training of the maintenance staff is important to get the most out of the acetate deicers used and to reduce the potential for under or over application. Short training videos and detailed application guidelines are available to the proactive manager. You may wish to contact your garage consultant for his recommendations or review the non-chloride, acetate-based deicers’ fact sheets available online.

Using the correct non-chloride acetate deicer during winter operations is part of the overall long-term preventative maintenance strategy for extending the lifecycle of a garage. This approach can save millions of dollars in future repair costs, reduce the inconvenience to the customer and reduce the potential for lost revenue while maintaining the beauty and value of the garage.